Warehouse automation brings you many advantages that make logistics processes more efficient. Other additional benefits include higher process speed and accuracy, resulting in savings.

Variability of different solutions

When deciding on a new solution for your warehouse, it is necessary to assess not only the current condition of the warehouse itself but also the return on a relatively challenging initial investment. Depending on your storage material it is most important to choose the right solution that is tailored to your needs.

Don’t be afraid of changes! Just think it right through…

- The first thought should be, if you would like build a new automated warehouse or rebuild an existing warehouse.

- Carefully review the area of the warehouse and the extent of the operations taking place there. Do you have a large warehouse with many work steps? Then, automation is a useful step.

- If your portfolio consists of small packaging units or highly specialized products, then automation is not the best solution for you. This also applies to cases where your products are subject to typical volume fluctuations or custom content.

Solutions, that bring progress

The starting points for your development lie in a multitude of variable possibilities. The use of automatic small parts stores is best for smaller products, different types of cartons, tray or tablet packaging.

For sensitive goods with clear handling points, special rack systems are used for carrierless goods with interoperable load carriers. And how does such a system work in practice? The goods are telescoped and stored in a special floor-free shelf on holding pins.

M.A.S. electric stackers are known for their excellent stability. As a result, their work is absolutely precise and perfectly reliable.

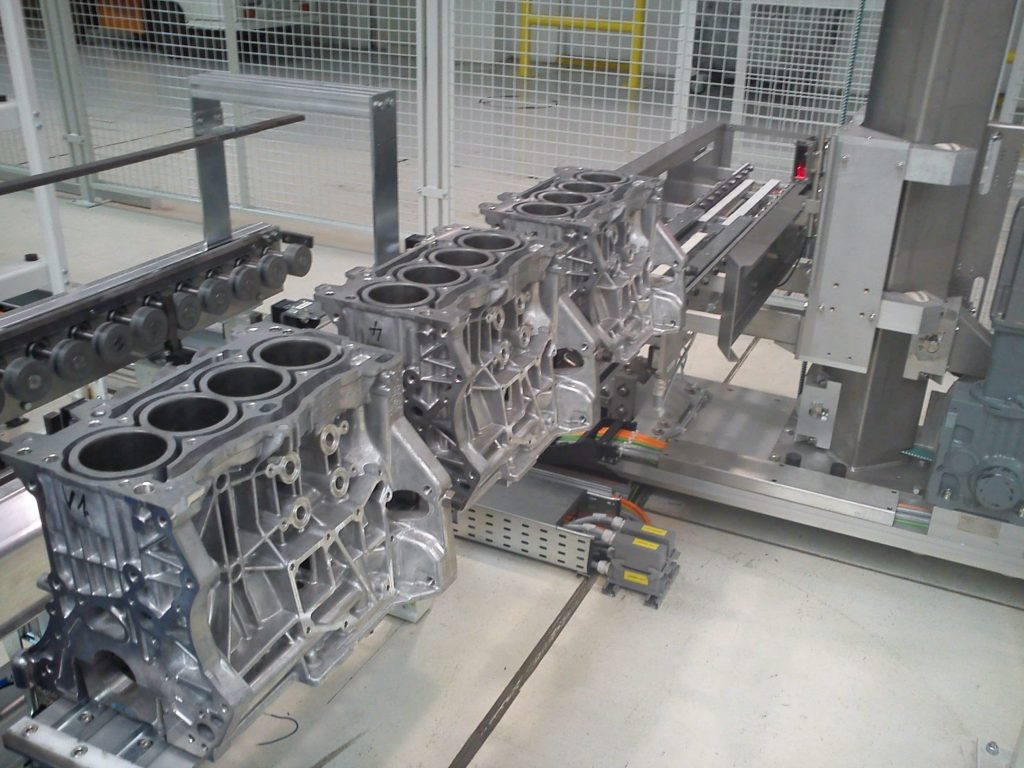

You can use another option if you are manipulating with large and heavy goods. These are storage and retrieval machines for full pallets and other demanding goods. These can be adapted to your requirements and are available in two versions – completely made of stainless steel or lacquered. They enable the universal use of a wide variety of goods.

It’s time to go one level higher

Due to the existing benefits you can move on your way back one step forward. And what are the concrete advantages of automation?

- The movement of goods is accelerated.

- Eliminates accidents, mistakes and losses caused by the human factor.

- Provides smooth, continuous operation.

- Reduces the costs of equipping certain employees.

- Brings comprehensive optimized processes and storage efficiency.

Improvements that you can hardly do without today

Warehouse automation is currently a necessary part of the development of the operation and efficiency of logistics. Do not be discouraged by a possible higher initial investment. If you consider everything carefully, you will profit from the positive benefits of the complex operation of the entire warehouse.